AWS made easy: 4 Intelligence Hub use cases

John Harrington

is the Chief Product Officer of HighByte, focused on defining the company’s business and product strategy. His areas of responsibility include product management, customer success, partner success, and go-to-market strategy.

If you’re moving industrial data to the cloud, you’re probably aware that AWS offers a breadth of services to store, catalog, analyze, and share operational information. Cloud services have become a key enabling tool in digital transformation because of their ability to store, process, and analyze large amounts of data in a centralized location.

HighByte recently joined the AWS Partner Network to help manufacturers contextualize and deliver data from their connected systems to the cloud with seamless efficiency. As stated by Sandrine Périno, Manufacturing and Industrial Global Partner Lead at AWS, “The Intelligence Hub delivers a modern approach to integrating factory floor systems with AWS cloud services. HighByte complements our edge strategy and aligns with our mission to optimize operations for Industrials by providing highly contextualized data ready for analysis.”

Manufacturers use cloud services differently depending on their specific needs, so we wanted to highlight the four primary ways our customers are connecting the Intelligence Hub to AWS. They include:

HighByte recently joined the AWS Partner Network to help manufacturers contextualize and deliver data from their connected systems to the cloud with seamless efficiency. As stated by Sandrine Périno, Manufacturing and Industrial Global Partner Lead at AWS, “The Intelligence Hub delivers a modern approach to integrating factory floor systems with AWS cloud services. HighByte complements our edge strategy and aligns with our mission to optimize operations for Industrials by providing highly contextualized data ready for analysis.”

Manufacturers use cloud services differently depending on their specific needs, so we wanted to highlight the four primary ways our customers are connecting the Intelligence Hub to AWS. They include:

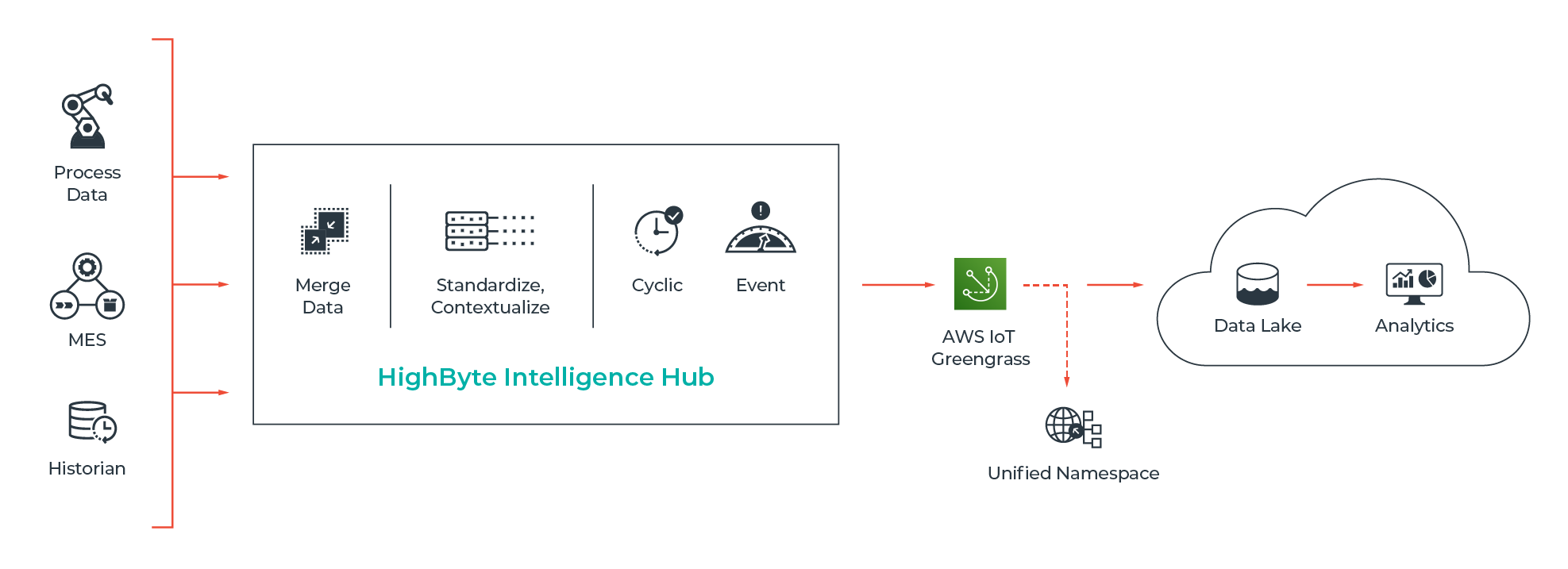

1. Multi-system integration

The plant floor is a complex environment of machinery, controllers, systems, data historians, and sensors that generate and log information. AWS provides several data on-ramps to the cloud, such as AWS IoT Greengrass, that allow manufacturers to collect, analyze, and manage data from multiple sources at scale. The challenge, though, is streamlining and translating this information into a usable and understandable format for the back office. The Intelligence Hub stitches together data from disparate systems by leveraging open standards—eliminating the need for time-consuming custom-coded integrations. Within the Intelligence Hub, the operational technology (OT) team can query a batch of data in real time from the relevant system (such as the MES, process historian, or machinery) to identify bottlenecks or quality issues, for example, and then publish it to the appropriate AWS service. From there, data scientists can access standardized, contextualized information in the cloud and apply more in-depth analytics to solve the problem they’re trying to address.

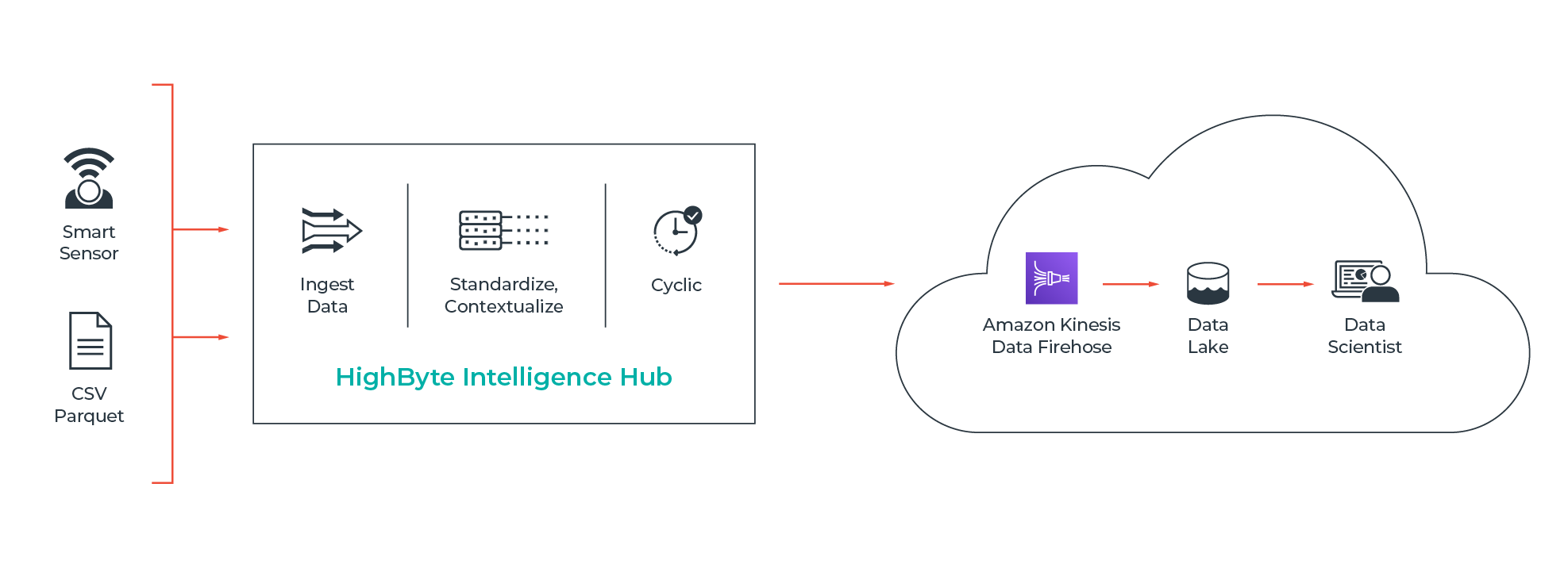

2. High-resolution data analytics

Smart sensors can create telemetry data in fractions of a second. So fast that the typical computer system can’t keep pace with the incoming feed, so many manufacturers buffer that data on the sensor or controller. Amazon Kinesis Data Firehose as an efficient way to send large volumes of streaming data to the cloud. The Intelligence Hub consumes the data, cleans it, and then sends it through Firehose to a data lake. One example is the use of IoT sensors for condition monitoring. If you’re tracking vibration on a continuously operating motor, you might require millisecond resolution data every 10 minutes. HighByte Intelligence Hub allows you to automate the retrieval of the data, structure and contextualize it, and then publish the information at high throughput to Amazon Kinesis on the AWS cloud.

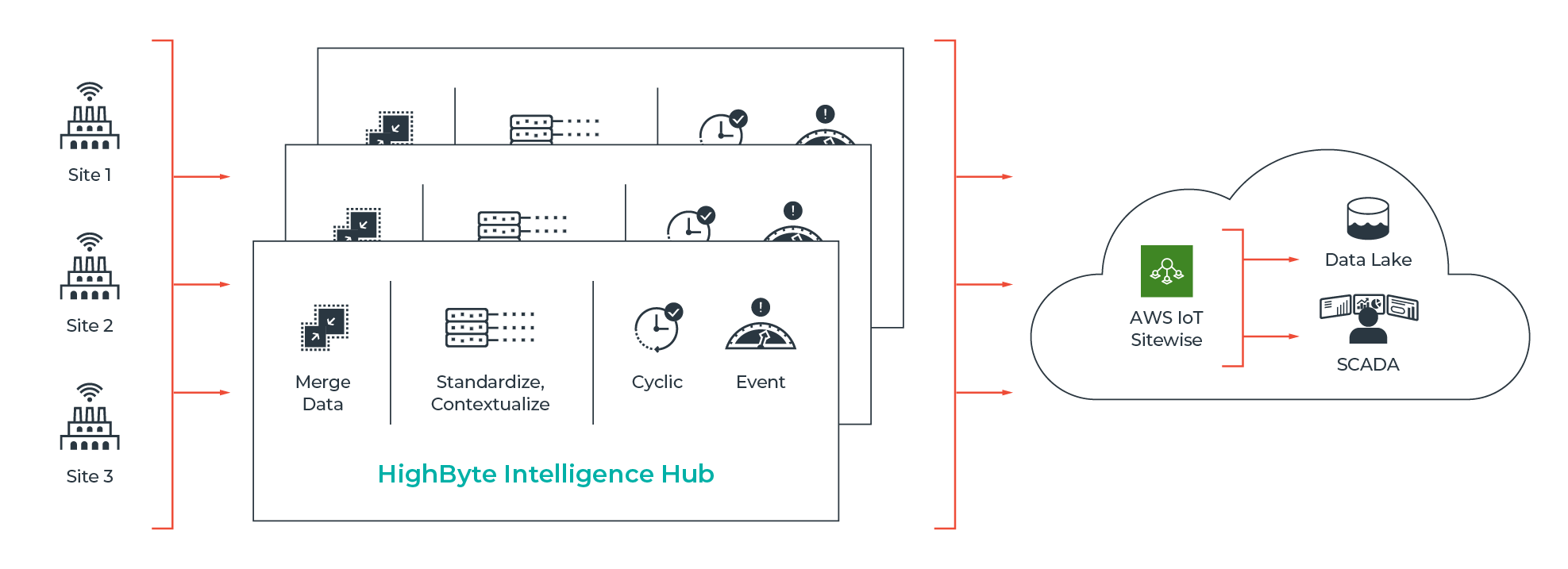

3. Multi-site monitoring

The above scenarios deal with single facilities. But what if you want to establish common operational performance metrics across multiple sites? You can deploy an Intelligence Hub at each plant and connect them to AWS IoT SiteWise for site-to-site comparisons and enterprise-wide visibility into overall performance. Whether you want to look at OEE, throughput, or maintenance variables, the Intelligence Hub can rationalize data, even from dissimilar systems across your plants, and pull all the information into a common format. From there, you can send the information to AWS IoT SiteWise to build models of assets, processes, and products to achieve accurate site comparisons, corporate-level dashboards, and KPIs.

4. From the cloud to the edge

In some cases, you might want to push insights from the cloud to the edge for action. HighByte Intelligence Hub enables bi-directional communication with AWS cloud services, so you can automate delivery of setpoints back to the machine or make a suggestion to the operator via the HMI or SCADA system. In the latter scenario, you empower the operators to make informed decisions based on their own experience and expertise. This way, you’re using analytics as guidance for operators rather than automating process changes that may not always be ideal for the unique operating conditions.

The Intelligence Hub simplifies the process of sending usable data to the extensive cloud-based services on AWS and back to the factory floor for actionable execution. I hope this post helped you better understand four common use cases powered by AWS and HighByte. Please read the AWS Architecture Blog for more information on how to connect the Intelligence Hub to AWS.

The Intelligence Hub simplifies the process of sending usable data to the extensive cloud-based services on AWS and back to the factory floor for actionable execution. I hope this post helped you better understand four common use cases powered by AWS and HighByte. Please read the AWS Architecture Blog for more information on how to connect the Intelligence Hub to AWS.

Get started today!

Download the software to get hands-on access to all the features and functionality within HighByte Intelligence Hub and start testing in your unique environment.