Industrial Data Fabric launches with an ecosystem

John Harrington

is the Chief Product Officer of HighByte, focused on defining the company’s business and product strategy. His areas of responsibility include product management, customer success, partner success, and go-to-market strategy.

As industrial organizations across the globe work toward digital transformation, many find the lack of readily accessible and usable data to be major barriers to success.

Manufacturers want to use operational data to drive automated decisions from machinery to the Cloud and put better information in the hands of business leaders. But depending on their data maturity, manufacturers often find that:

- Their operational data is not standardized. Each machine and system has different formats, labels, units of measure, and available information.

- The data that is readily available was designed for process automation and is not adequate for digital transformation use cases. Additional data exists, but it has not been collected, collated, or contextualized for analysis.

- The tools available to collect and work with the data were designed for IT teams. However, the best and most efficient way to contextualize and clean data is to leverage the domain experts of the source systems. In manufacturing companies, these domain experts are typically operational technology (OT) engineers.

- IT/OT infrastructure is missing or weak. There is a tangle of inherent complexities across systems, processes, and teams.

The result of these challenges is the inability to scale. Even projects that manage to get rolled out are difficult and expensive to maintain, and therefore digital transformation goals are not met.

With data difficulties building the biggest barriers to the realization of Industry 4.0, manufacturers recognize they need to change the way they think about digital infrastructure. According to Deloitte, 86% of manufacturers believe that smart factories will be the main driver of competition by 2025, but 65% report no progress on their own smart initiatives, citing a lack of necessary IT infrastructure and broader integration between IT and OT as major barriers.

Industrial data sources might include telemetry data from equipment and smart sensors, MES and ERP transactional and master data, historian time series databases, events, documents, 3D models, lab and test data, images, simulators, and P&IDs (Piping and Instrumentation Diagrams). Organizing, maintaining, and adding proper context to all this data from all these data sources across all of a company's plants is a colossal challenge that indicates the real question industrial leaders are struggling to answer:

How can we transform the data we need from inherently incompatible sources into meaningful information?

Industrial data sources might include telemetry data from equipment and smart sensors, MES and ERP transactional and master data, historian time series databases, events, documents, 3D models, lab and test data, images, simulators, and P&IDs (Piping and Instrumentation Diagrams). Organizing, maintaining, and adding proper context to all this data from all these data sources across all of a company's plants is a colossal challenge that indicates the real question industrial leaders are struggling to answer:

How can we transform the data we need from inherently incompatible sources into meaningful information?

It takes an ecosystem

To overcome these major barriers to Industry 4.0 adoption, AWS announced a new offering, Industrial Data Fabric, at Hannover Messe in April 2023. The Industrial Data Fabric offering gives customers a framework that combines AWS cloud services, ISV partner solutions, and services from global system integrators with guidance and reference architectures. The goal of the Industrial Data Fabric offering is to help customers conquer their most pressing business use cases at scale and pace.

This takes an ecosystem of partners with a shared vision who are dedicated to making this work for the customer.

That’s why we’re excited to be a core solution partner for the Industrial Data Fabric launch. HighByte recently announced an integrated solution with Element that enables customers to build best-of-breed data operations from the shop floor to the Cloud. The AWS-powered architecture integrates Element Unify and HighByte Intelligence Hub to give both IT and OT users the tools they need to contextualize and normalize data into rich information for analytics and other business systems.

To address the challenge of scalability, the solution is designed to be maintainable and adaptable across the enterprise, helping industrial customers achieve economies of scale as they increase the quantity of use cases that rely on industrial data.

This takes an ecosystem of partners with a shared vision who are dedicated to making this work for the customer.

That’s why we’re excited to be a core solution partner for the Industrial Data Fabric launch. HighByte recently announced an integrated solution with Element that enables customers to build best-of-breed data operations from the shop floor to the Cloud. The AWS-powered architecture integrates Element Unify and HighByte Intelligence Hub to give both IT and OT users the tools they need to contextualize and normalize data into rich information for analytics and other business systems.

To address the challenge of scalability, the solution is designed to be maintainable and adaptable across the enterprise, helping industrial customers achieve economies of scale as they increase the quantity of use cases that rely on industrial data.

How does the integration work?

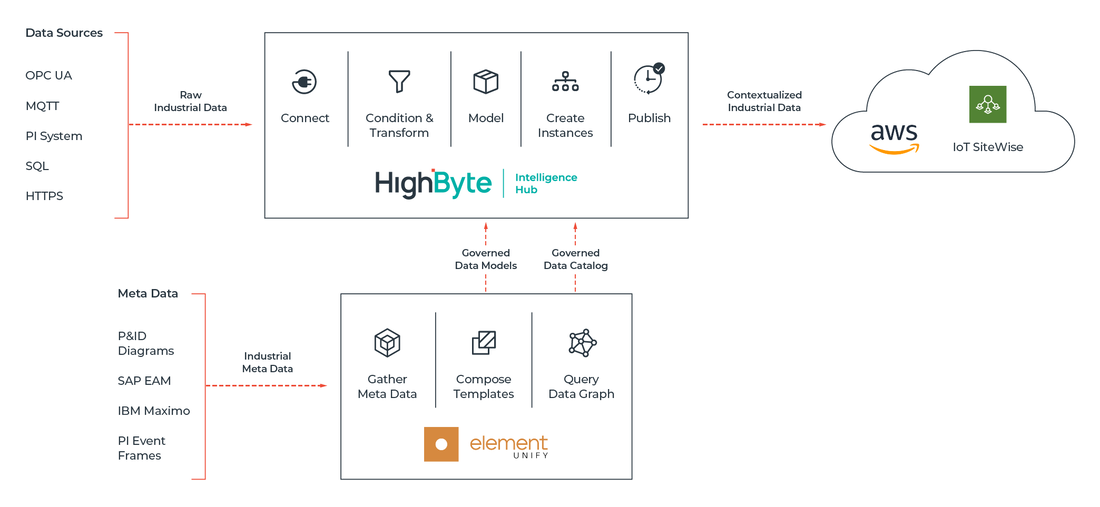

In this architecture, customers create and manage standardized and contextualized operational models in Element Unify and then transfer these models to federated instances of HighByte Intelligence Hub at the site. The edge-native hubs connect to OT and IT source systems, transform and contextualize this data, and then stream data payloads to AWS IoT SiteWise. This architectural approach allows operations teams to provide data to the AWS cloud for systems and business users in an efficient and managed way.

Figure 1: Example architectural reference diagram for AWS’s Industrial Data Fabric offering featuring Element Unify and HighByte Intelligence Hub.

In this architecture, Element Unify becomes a data model repository for the enterprise. When data is needed for new lines, assets, or sites, HighByte Intelligence Hub consumes governed models from Element Unify and maps industrial data sources to these models within the Intelligence Hub. These data sources may include OPC UA servers, smart sensors, SCADA systems, process historians, relational databases, and REST APIs. The Intelligence Hub also enables users to write events and prescriptive guidance back to these operational data sources.

In the last stage of this architecture, HighByte Intelligence Hub can publish both models (governed by Element Unify) and data to AWS IoT SiteWise where it is now ready to be processed for business insights. Together, HighByte Intelligence Hub and Element Unify allow data to be collected, contextualized, and delivered at a resolution that is unique for each smart manufacturing use case.

In the last stage of this architecture, HighByte Intelligence Hub can publish both models (governed by Element Unify) and data to AWS IoT SiteWise where it is now ready to be processed for business insights. Together, HighByte Intelligence Hub and Element Unify allow data to be collected, contextualized, and delivered at a resolution that is unique for each smart manufacturing use case.

What’s next?

Industrial Data Fabric’s architectural approach allows operations teams to provide data to both systems and business users much more efficiently. With this solution, operations teams can own and manage data access, accelerate analytics projects, and maintain site flexibility as they change or add new machinery, assets, and processes over time.

In the coming weeks, this offering will be brought to market through global system integrator launch partners that include Deloitte, Infosys, Cyient, and TensorIoT. These boots on the ground are the last mile between concept and reality.

The Industrial Data Fabric offering represents a major step toward scaling digital transformation projects across the enterprise and achieving sustainable business practices with real ROI. If you want to learn more about Industry 4.0 and what is needed to achieve it, please read the whitepaper, “DataOps: The Missing Link in Your Industrial Data Architecture.”

Special thanks to HighByte CTO Aron Semle, AWS Principal Partner Solutions Architect Rajesh Gomatam, and AWS Strategic Solutions Architect Scott Robertson who contributed to this article.

In the coming weeks, this offering will be brought to market through global system integrator launch partners that include Deloitte, Infosys, Cyient, and TensorIoT. These boots on the ground are the last mile between concept and reality.

The Industrial Data Fabric offering represents a major step toward scaling digital transformation projects across the enterprise and achieving sustainable business practices with real ROI. If you want to learn more about Industry 4.0 and what is needed to achieve it, please read the whitepaper, “DataOps: The Missing Link in Your Industrial Data Architecture.”

Special thanks to HighByte CTO Aron Semle, AWS Principal Partner Solutions Architect Rajesh Gomatam, and AWS Strategic Solutions Architect Scott Robertson who contributed to this article.

Get started today!

Download the software to get hands-on access to all the features and functionality within HighByte Intelligence Hub and start testing in your unique environment.